Overview

Integrating the control systems with the business processes and ERP systems for real-time monitoring.

The manufacturing sector, the producer of about one-third of all data generated today and slated to significantly increase in the coming years, is facing constant challenges. In order to deliver innovative, quality products at ever-competitive prices while meeting global safety standards, the industry needs technologies that can make business sense of this data and offer insights that can improve performance and predict challenges.

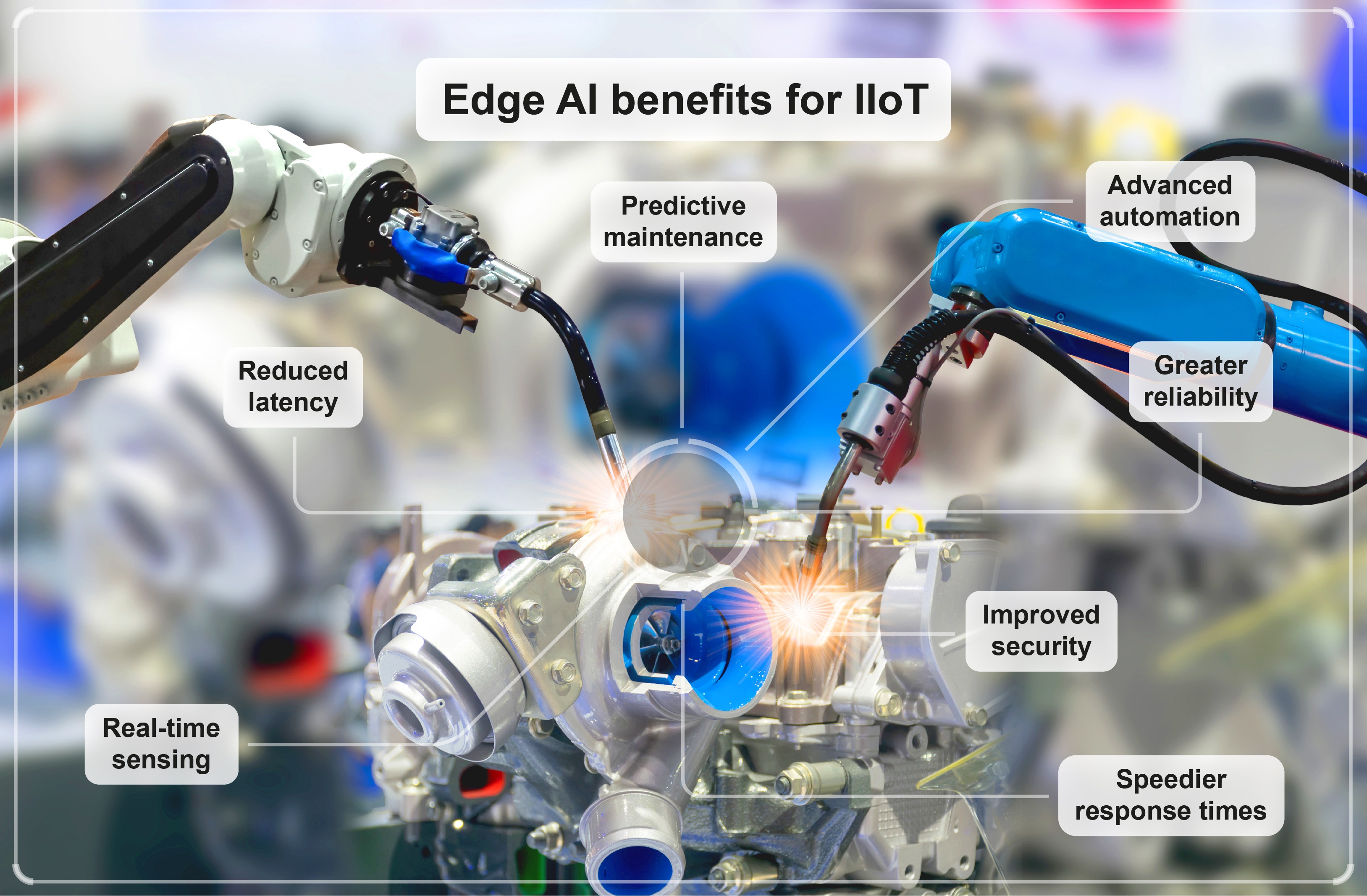

Manufacturing companies need to focus more on optimizing quality, productivity and efficiencies in their product line, eliminate downtime and step up warehouse management and distribution with better utilization of human and machine resources. The existing solutions do not provide complete management and monitoring of productivity, or real-time monitoring. Technologies that can pre-empt downtime and detect issues before they become business challenges, real time, are the need of the day.

Optimal utilization of energy and resources can be ensured by transparency and clear flow of information from various data collation points, providing a clear communication dashboard that keeps everyone on the same page. For this, we need solutions that will enable devices and data sources to talk to each other- clearly – A software solution to monitor, manage and optimize production and real-time operations to reduce cost and time, that meets the dynamic, constantly evolving needs of the industry while providing seamless communication and hence data collation across nodal points.